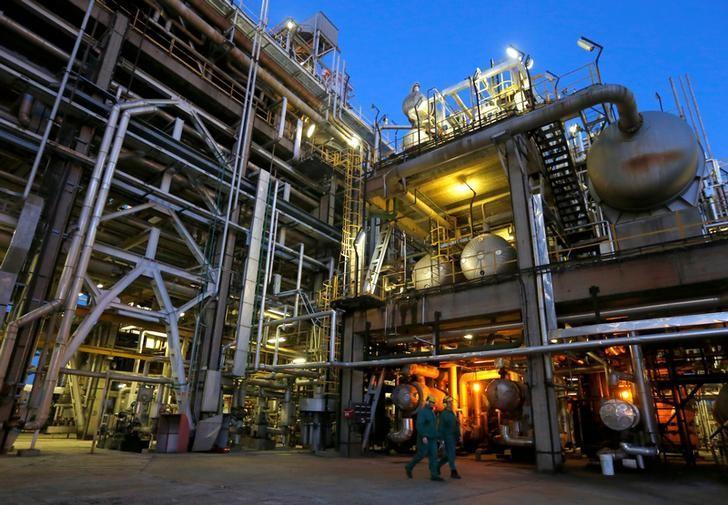

Refinery continues their digital transformation and wins second Plant of the Year Award

In one of the all-time greatest cases of not resting on laurels, MOL Danube Refinery near Budapest has become the first repeat winner of FieldComm Group (FCG) Plant of the Year Award in its almost 15-year history. MOL Danube’s engineers and technicians integrated more than 4,135 HART valves and instruments with its computerized maintenance management system (CMMS) and controls to win in 2010, and more recently, expanded and extended their proactive maintenance strategy to other applications and departments to achieve similar benefits.

Not only have they continued to add smart devices and enhanced their valve diagnostics and predictive maintenance, but they’re saving $350,000 per year on potential shutdowns with smart device monitoring; set up a cross-functional, risk-assessment team that evaluates 20,000 device notifications per year, and started a digital transformation program.

To forge ahead after winning their 2010 Plant of the Year Award, Bereznai, Bartók and their colleagues have launched expansions and multiple diagnostic and maintenance projects to bring similar benefits to other facilities at MOL Danube. So far, they’ve pushed its use of FieldComm Group technologies up to 3,680 HART devices, 413 Foundation Fieldbus devices and 42 WirelessHART devices and six gateways, which receive signals from 32 wireless devices usually measuring temperature and corrosion. They’re also planning to adopt HART-IP (Internet protocol) with their OSIsoft PI historian and software. This adds up to about 4,700 intelligent instruments on the 15 units connected to SAP-PM CMMS.

“MOL Danube has executed many reliability improvements since 2008 by using OSIsoft PI as an operations technology (OT) data infrastructure for predictive, proactive analytics,” adds Tibor Komróczki, head of process information and automation at MOL Danube. “PI delivers strategic business value through 400,000 tags in four high-availability (HA) collectives. Server virtualization and HA configuration have reduced maintenance and hardware costs and increased system availability. The system contains 300 smart-element and 150 notification templates complemented by 61,000 event frames including dynamic solutions. MOL is also rolling out Microsoft Azure-based machine learning (ML) to let enterprise intelligence reinforce use of data and establish analytics-based decisions. Digital transformation is reengineering workflow around enhanced and consistent information and changing data management paradigms.”